Cork in Aerospace: South Korea’s NURI Rocket

Amorim Thermal Protection System Powers South Korea’s NURI Rocket

![]()

Our Aerospace grade materials constituents and structure make them ideal thermal protection materials with excellent ablation and insulating properties, maintaining a low weight to low thermal conductivity performance, creating a sturdy char layer that protects the inner material, maintaining its integrity and slowing thermal degradation.

We’ve been part of several development programs for aerospace ablative materials such as Aerofast, Ablamod, Retalt, and SALTO, paving the way for next-generation materials that are lighter and more efficient in thermal protection.

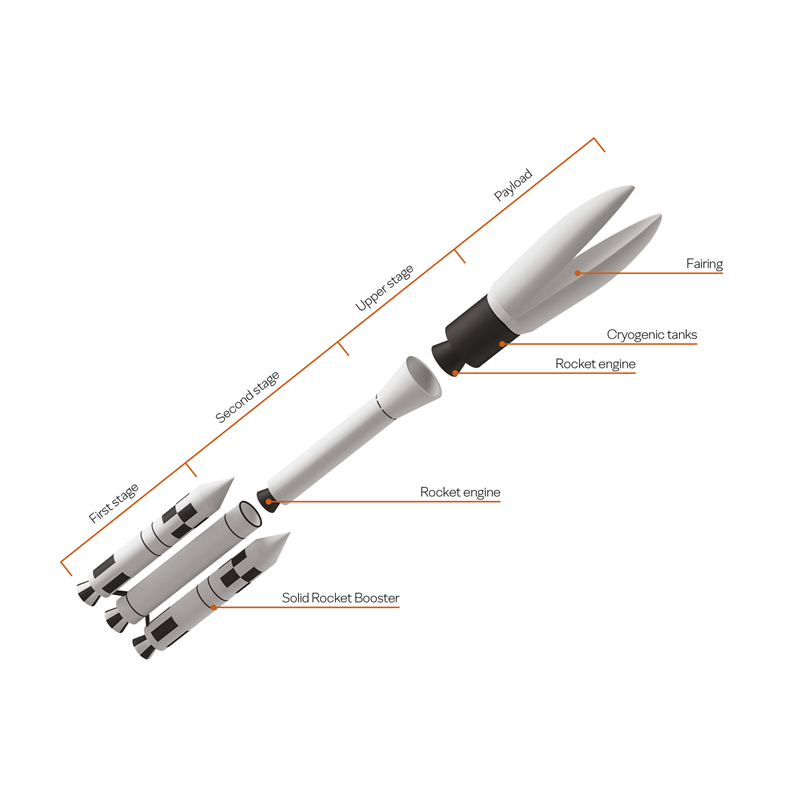

From the first ignition to payload delivery, Amorim Cork Solutions provides advanced thermal protection and ablative systems for the most critical parts of an Expendable Launch Vehicle System (ELVS).

Our materials are integrated into Solid Rocket Boosters, rocket engines, cryogenic tanks, and payload fairings, ensuring resistance to extreme temperatures, vibration, and mechanical loads during launch, flight, and re-entry.

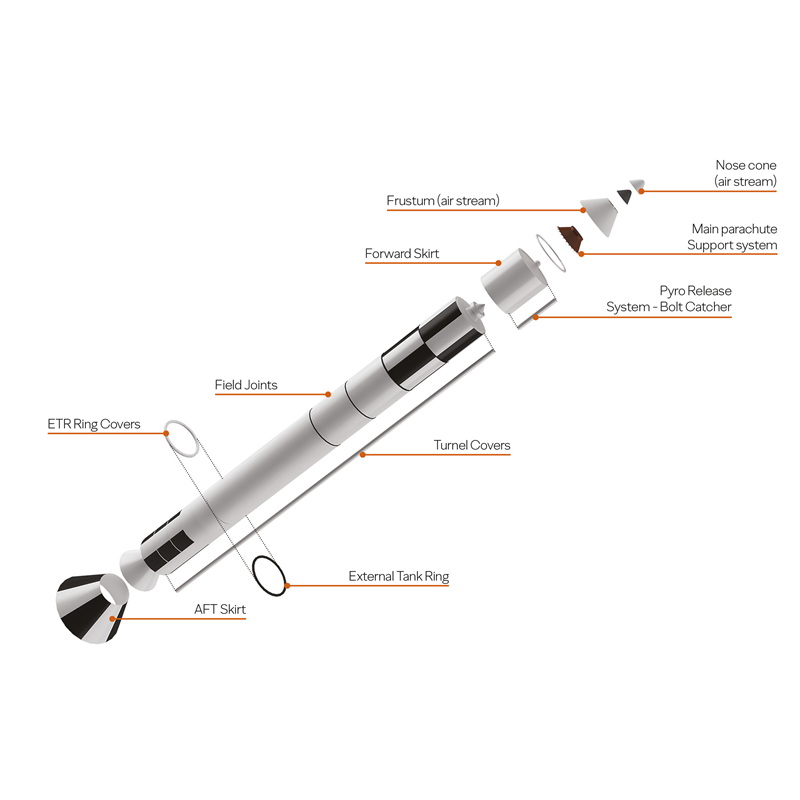

Zooming in on the Solid Rocket Boosters, Amorim solutions are applied to the nose cone, frustum, forward and aft skirts, external tank ring covers, field joints, and tunnel covers.

These high-performance ablative and insulating systems protect structural integrity, control thermal stress, and enhance mission reliability, meeting the demanding requirements of modern space programs.

Our products are engineered for seamless integration into aerospace systems. They bond easily to most substrate materials using designated adhesive systems, and can be finished with specialized coatings or varnishes for enhanced performance. Each part can be precision-trimmed and machined to the required geometry, ensuring perfect fit and functionality, and is readily integrated into FRP (fiber-reinforced plastic) structures. In addition, we offer 3D-molded components, delivering labor savings, faster assembly, and greater application efficiency.

| Material Properties | P45 | P50 |

|---|---|---|

| Cork particle size (mm) | 1/2 | 0,5/1 |

| Sheet dimension (mm) | 1270x710 | 1270x710 |

| Density @ 20° C (Kg/m3) (1) | 304-336 | 448-512 |

| Tensile strength (MPa) (2) | >0.86 | >1.73 |

| Thermal conductivity (W/m•K)(3) | 0.06 | 0.07 |

| Specific heat (KJ/Kg/°K)(4) | 2.5 | 2.1 |

| Substrates to bond | Metal and Composite | |

(1) ASTM F1315 (2) ASTM F152, Method B (3) ASTM C177 (4) ASTM C351 (5) indicative value (6) also available in molded pieces

The data provided in this table represents typical values. This information is not intended to be used as a purchasing specification and does not imply suitability for use in a specific application. Failure to select the proper product may result in either equipment damage or personal injury. Please contact us regarding specific application recommendations. Amorim Cork Solutions expressly disclaims all warranties, including any implied warranties of merchantability or fitness for a particular purpose. Amorim Cork Solutions is not liable for any indirect, special, incidental, consequential, or punitive damages as a result of using the information listed in this table. Any of its material specification sheets, its products, or any future use or re-use of them by any

Our engineering team works closely with customers to address technical challenges and support the development of customized materials and solutions, precisely tailored to the requirements of each aerospace program. From initial concept to qualification and production, we provide expert guidance to ensure optimal performance, reliability, and integration into your systems.

Amorim Thermal Protection System Powers South Korea’s NURI Rocket

Amorim Cork Solutions contributes to Europe’s first full-scale reusable rocket test with cork-based TPS

Amorim Cork Solutions’ lightweight cork TPS debuts in NASA’s BOLE DM-1 static fire, protecting next-gen Artemis boosters bound for the Moon and beyond.